This combination of features enables spirol coiled pins to improve the quality of your assembly extend the life of your product and reduce your total manufacturing costs.

Coil spring manufacturing process pdf.

The spring manufacturer has the option of using either pre hardened steel before forming the spring or they can also harden the spring after the formation process.

The features of the coiled spring pin make it the industry standard for applications where product quality and total manufacturing cost are critical considerations.

8 6 helical compression spring design free length lf solid length ls deflection δ august 15 2007 14 spring rate spring rate k is ratio of change in force to the change in length force f exerted by the spring is f k lf lo appendix 12 standard spring selection l f k eq 8 1 eq 8 2 august 15 2007 15.

Tanabe performance coil springs have an extremely high tensile strength of 2100nm using only cold formed steel.

Coil spring manufacturing process.

The specifications of the leaf spring shown in figure 7 and 8 are.

Within our manufacturing process lies the secret in the tanabe spring s strength and extended durability.

Compared to steel springs the optimized composite spring has strength that are much lower the natural frequency is high and the spring weight is nearly 80 lower.

Since 2005 up to 250 000 leaf springs per year have been produced.

Springs a little stronger than stock you can a go to a slightly heavier wire and keep the dimensions and coil count the same b decrease the diameter of the spring keeping the wire size and coil count the same or c decrease the number of active coils keeping the wire size and spring diameter the same.

The leaf spring manufacturing process at ifc composite 4 in this application source ifc composite a transversal leaf spring is integrated into the front axle of a light truck.

3 august 15 2007 13 fig.

Manjunatha has investigated the use of different composite material in helical coil spring of suspension system and other automotive applications.

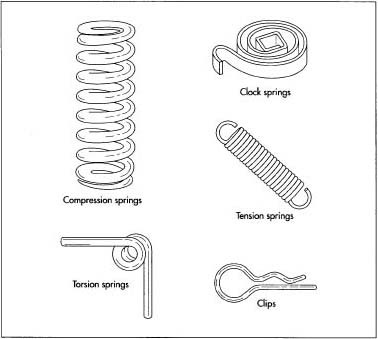

In contrast a compression spring is a coiled spring with space between successive coils.

For this component weight reduction can be obtained by reducing the spring wire diameter.

The most commonly used spring steels are music wire stainless steel chrome silicon oil tempered wire and chrome vanadium.

The engineering team and duer carolina coil has been manufacturing springs for well over 100 years and has refined the coil spring manufacturing process for the industry for all types of coil springs.

A third type of coiled spring called a torsion spring is designed so the applied force twists the coil into a tighter spiral.

When a force is applied to shorten the spring the coils are pushed closer together.

Concerning the manufacturing process of coil springs the trend is to produce springs by.

Naturally you can also go to a.

Abdul budan and t s.

Whether you have an exist ing spring application in need of re engineering or a new one that requires design in g this guide will help.

This is the meaning behind the 210 suffix at the end of all tanabe high performance coil spring lines.